商铺名称:西安骏焊焊材有限公司

联系人:郑经理(先生)

联系手机:

固定电话:

企业邮箱:1661780919@qq.com

联系地址:雁塔区太白南路东侧新一代国际公寓1幢1单元

邮编:710000

联系我时,请说是在焊材网上看到的,谢谢!

LB-52NSU日本神钢焊条 低合金低温钢高强钢焊条进口焊条进口焊丝

西安骏焊专业销售日本神钢焊条焊丝

When pipe root pass welding must be conducted from outside rather than inside in order to form the back bead inside the pipe, GTAW or SMAW are generally favored. Kobe Steel has long marketed FAMILIARC? LB-52U as well as FAMILIARC? LB-62U for this purpose, and they still serve as Kobe’s most reliable, “one and only” products worldwide.

In addition to meeting the always-changing and diverse specifications of pipelines, TRUSTARC? LB-52NSU has been developed specifically for root pass welding of pipes for low temperature service. It is a covered, low hydrogen type electrode equivalent to AWS A5.5 E7016-G. It offers superb notch toughness at -60°C and very low diffusible hydrogen content of about 3.0ml/100g. The chemistries, mechanical properties of all weld metal and diffusible hydrogen content of TRUSTARC? LB-52NSU are shown in Tables 3, 4 and 5 respectively.

Table 1: Covered electrodes for girth welding|

API 5L pipe grade |

Welding pass |

Low hydrogen type |

High cellulose type |

|

|---|---|---|---|---|

|

Vertical upward position |

Vertical downward position |

|||

| X42-X52 | Root |

LB-52U LB-52NSU |

LB-78VS | KOBE-6010 |

| Hot |

LB-52-18 LB-52NS |

|||

| Filler & Cap | ||||

| X56-X60 | Root |

LB-52U LB-52NSU |

KOBE-6010 KOBE-7010S |

|

| Hot |

LB-52-18 LB-52NS |

KOBE-7010S | ||

| Filler & Cap | ||||

| X65 | Root | LB-52U | LB-88VS |

KOBE-7010S KOBE-8010S |

| Hot |

LB-62 LB-62D |

|||

| Filler & Cap | KOBE-8010S | |||

| X70 | Root | LB-62U |

KOBE-7010S KOBE-8010S |

|

| Hot |

LB-62 LB-62D |

|||

| Filler & Cap | KOBE-8010S | |||

| X80 | Root | LB-62U |

LB-98VS LB-108VS |

—— |

| Hot |

LB-65D LB-106 |

|||

| Filler & Cap | ||||

| X100 | Root | —— | LB-118VS | —— |

| Hot |

LB-80L LB-116 |

|||

| Filler & Cap | ||||

|

API 5L pipe grade |

Welding pass |

Temperature (°C) | ||

|---|---|---|---|---|

| -20 | -40 | -60 | ||

| X42-X56 | Root & Hot |

TG-S50 MX-100T |

TG-S1N MX-A55T |

|

| Filler & Cap |

DW-A50 DW-A50SR |

DW-A55E DW-A55ESR |

DW-A55L DW-A55LSR DW-A81Ni1 |

|

| X60 | Root & Hot | TG-S62 | TG-S60A | |

| Filler & Cap |

DW-A55E DW-A55ESR |

DW-A55L DW-A55LSR DW-A81Ni1 |

||

| X65 | Root & Hot | TG-S62 | TG-S60A | |

| Filler & Cap |

DW-A55E DW-A55ESR |

DW-A55L DW-A55LSR DW-A81Ni1 |

||

| X70 | Root & Hot | TG-S62 | TG-S60A | |

| Filler & Cap | DW-A70L |

DW-A55L DW-A81Ni1 |

||

| X80 | Root & Hot | TG-S80AM | ||

| Filler & Cap | DW-A70L | —— | ||

| X100 | Root & Hot | TG-S80AM | ||

| Filler & Cap | DW-A80L | —— | —— | |

| C | Si | Mn | P | S | Ni | Ti | B |

|---|---|---|---|---|---|---|---|

| 0.06 | 0.62 | 1.25 | 0.016 | 0.004 | 0.50 | 0.014 | 0.0027 |

| Tensile properties | Notch toughness | ||||||

|---|---|---|---|---|---|---|---|

|

0.2% PS (MPa) |

TS (MPa) |

EI (%) |

RA (%) |

Absorbed energy:J (Brittle fracture: %) |

FATT (°C) |

||

| -80°C | -60°C | -40°C | |||||

| 511 | 598 | 32 | 78 |

43(60) 55(60) 41(60) Av.46(60) |

44(55) 72(55) 58(52) Av.58(54) |

70(50) 137(35) 144(35) Av.117(40) |

-53 |

| Electrode dia (mm) | 1 | 2 | 3 | 4 | Ave. |

|---|---|---|---|---|---|

| 3.2 | 2.8 | 3.3 | 3.5 | 3.0 | 3.2 |

Note: Tested method: According to AWS A4.3.(Gas chromatography)

Welding current: 120 A (DCEP)

Welding atmosphere: 21°C x RH10%

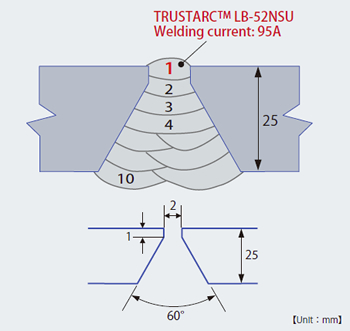

Figure 3: Groove shape and pass sequence of butt joint

welding with TRUSTARCTM LB-52NSU(root pass only)

and TRUSTARCTM LB-52NS

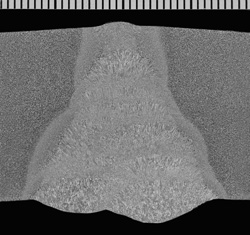

In welding a butt joint on a 25 mm thick plate, 3.2 mm dia. TRUSTARC? LB-52NSU was used for the root pass with DC 95 amp, and 3.2 mm dia. TRUSTARC? LB-52NS was used for the second pass onwards with DC 110 amp in the vertical upward position. The preheating and interpass temperatures were kept between 115 and 135°C. Figure 3 shows the groove shape and the pass sequence and Figure 4, the macrostructure of the weld metal. The chemistries and the tensile properties are shown in Tables 6 and 7, respectively and the notch toughness properties and the transition curve of the butt joint weld metal are shown in Table 8 and Figure 5, respectively. (Note: both TRUSTARC? LB-52NSU and TRUSTARC? LB-52NS are specified as AWS A5.5 E7016-G).

Figure 4: Macrostructure of butt joint weld

metal

| Location | C | Si | Mn | P | S | Ni | Ti | B |

|---|---|---|---|---|---|---|---|---|

| Face | 0.07 | 0.31 | 1.40 | 0.008 | 0.003 | 0.50 | 0.013 | 0.0022 |

| Reverse | 0.08 | 0.30 | 1.36 | 0.009 | 0.003 | 0.43 | 0.014 | 0.0023 |

| Location | Tensile properties | |||

|---|---|---|---|---|

| Center |

0.2%PS (MPa) |

TS (MPa) |

El (%) |

RA (%) |

| 506 | 577 | 25 |

81 |

|