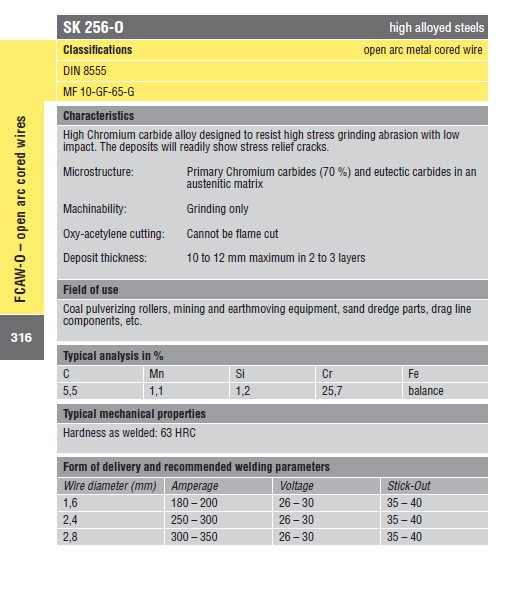

SK 256-O high alloyed steels

Classifications open arc metal cored wire

DIN 8555

MF 10-GF-65-G

Characteristics

High Chromium carbide alloy designed to resist high stress grinding abrasion with low

impact. The deposits will readily show stress relief cracks.

Microstructure: Primary Chromium carbides (70 %) and eutectic carbides in an

austenitic matrix

Machinability: Grinding only

Oxy-acetylene cutting: Cannot be flame cut

Deposit thickness: 10 to 12 mm maximum in 2 to 3 layers

Field of use

Coal pulverizing rollers, mining and earthmoving equipment, sand dredge parts, drag line

components, etc.

Typical analysis in %

C Mn Si Cr Fe

5,5 1,1 1,2 25,7 balance

Typical mechanical properties

Hardness as welded: 63 HRC

Form of delivery and recommended welding parameters

Wire diameter (mm) Amperage Voltage Stick-Out

1,6 180 – 200 26 – 30 35 – 40

2,4 250 – 300 26 – 30 35 – 40

2,8 300 – 350 26 – 30 35 – 40