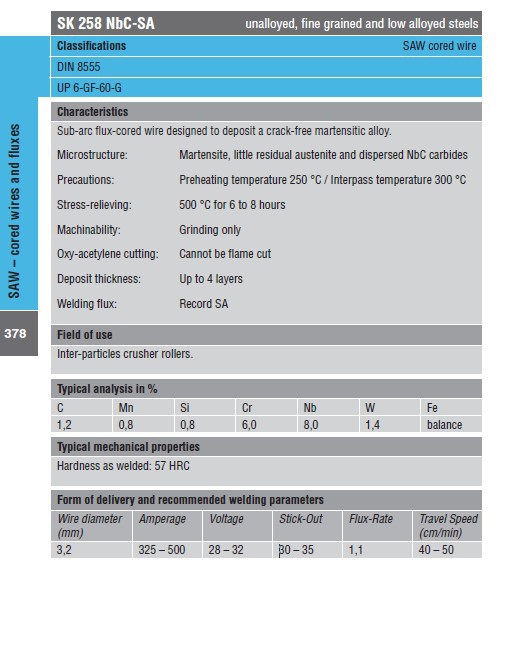

SK 258 NbC-SA unalloyed, fine grained and low alloyed steels

Classifications SAW cored wire

DIN 8555

UP 6-GF-60-G

Characteristics

Sub-arc flux-cored wire designed to deposit a crack-free martensitic alloy.

Microstructure: Martensite, little residual austenite and dispersed NbC carbides

Precautions: Preheating temperature 250 °C / Interpass temperature 300 °C

Stress-relieving: 500 °C for 6 to 8 hours

Machinability: Grinding only

Oxy-acetylene cutting: Cannot be flame cut

Deposit thickness: Up to 4 layers

Welding flux: Record SA

Field of use

Inter-particles crusher rollers.

Typical analysis in %

C Mn Si Cr Nb W Fe

1,2 0,8 0,8 6,0 8,0 1,4 balance

Typical mechanical properties

Hardness as welded: 57 HRC

Form of delivery and recommended welding parameters

Wire diameter

(mm)

Amperage Voltage Stick-Out Flux-Rate Travel Speed

(cm/min)

3,2 325 – 500 28 – 32 30 – 35 1,1 40 – 50