商铺名称:广州三合自动化设备有限公司

联系人:方春雷(先生)

联系手机:

固定电话:

企业邮箱:2382119668@qq.com

联系地址:广州市南沙区榄核镇数码花园一座九梯201室

邮编:

联系我时,请说是在焊材网上看到的,谢谢!

|

西门子工业自动化与驱动集团合作伙伴 |

广州三合自动化设备有限公司 |

|

联 系 人: |

阿 拉 雷 |

|

电 话 : |

o 2 o - 3 9 o o 8 7 5 9 |

|

手 机: |

1 7 7 2 8 (微*)1 9 8 3 3 1 |

|

传 真: |

o 2 o - 3 9 o o 8 7 5 9 |

|

商务 QQ : |

2 3 8 2 1 1 9 6 6 8 |

|

公司地址: |

广州市南沙区金岭北路252号1704房 |

1、概述

基于WinCC/B.Data的综合能源管理系统,是西门子公司集成于TIA全集成自动化 & TIP全集成能源自动化的一体化产品,通过这一强有力的工具,对从SCADA层中得到的数据,采用成熟高效的综合能源分析方式,覆盖能源采购,能源调度,确保能源的高效使用和良好的成本控制。

采用B.Data进行能源系统的分析及管理,最终实现:

相应的分析结果,通过报表系统合理展示;

B.Data主要对工厂能源数据进行分析,其数据来源有多种方式,可以基于从WinCC、OPC、ODBC、FTP等多种方式进行数据采集。本文主要讲述了在B.Data 5.3中基于OPC的方式如何实现能源数据采集。

2、实例介绍

在WinCC中建立3个浮点数:TestTag1,TestTag2,TestTag3;

以WinCC为OPCServer,在B.Data中进行相应配置基于OPC进行数据采集。

3、WinCC中配置

3.1 建立变量

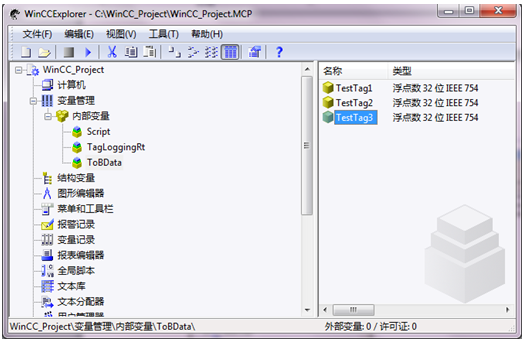

如下图1在WinCC中建立相应变量:

TestTag1:浮点数

TestTag2:浮点数

TestTag3:浮点数

图1:WinCC中建立相应变量

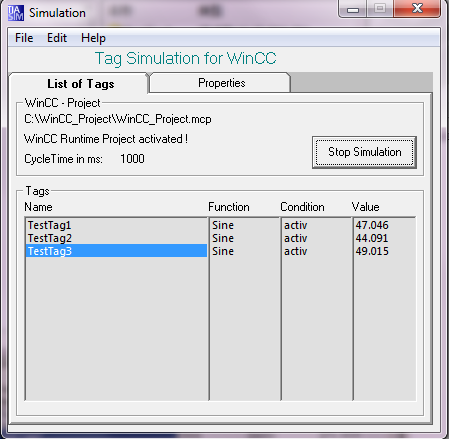

3.2 仿真器仿真数据

因为是建立的内部变量,需要在仿真器中仿真数据:

图2:仿真器中仿真数据

4、B.Data项目设计

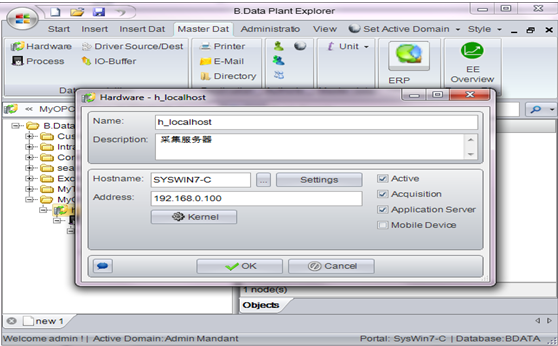

4.1 创建采集服务器

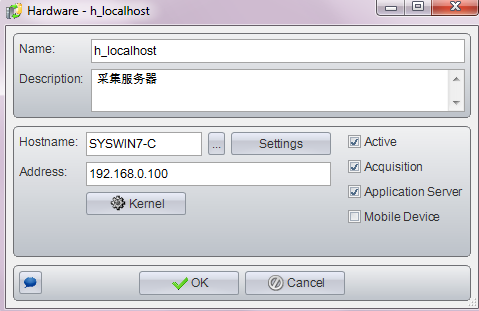

本例中采集服务器与功能服务器在同一台机器上,所以Hostname是本机,如果采用分布式结构,需要配置主机名和地址为采集服务器的主机名和IP地址。同时需要注意,一定不要采用Hostname为Localhost,IP地址为127.0.0.0.1,通讯是不成功的。

图3:创建采集服务器

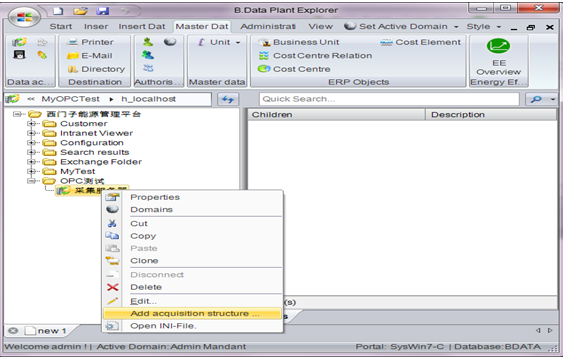

4.2 配置变量

创建采集服务器后,需要配置OPC组态并添加变量:

图4:打开配置采集服务器窗口

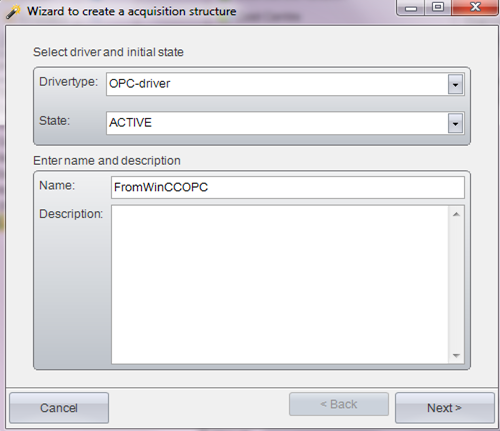

图5:配置OPC采集驱动器

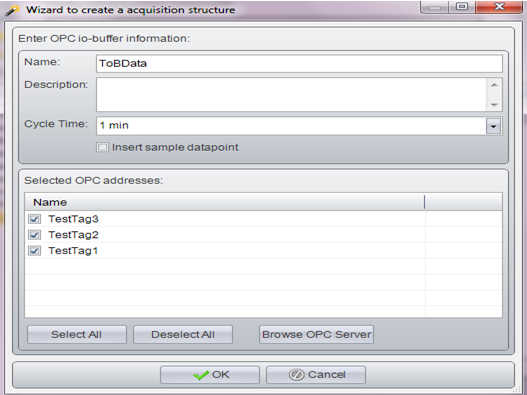

图6:创建OPC采集组

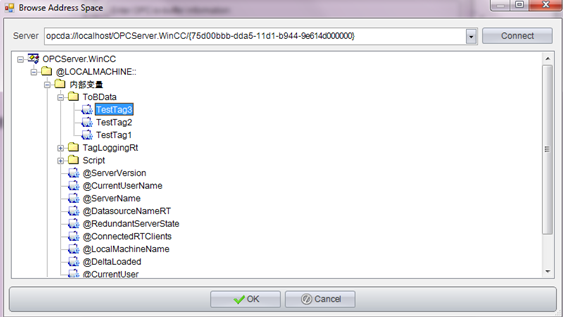

图7 选择WinCC中的变量步骤1

图8 选择WinCC中的变量步骤2

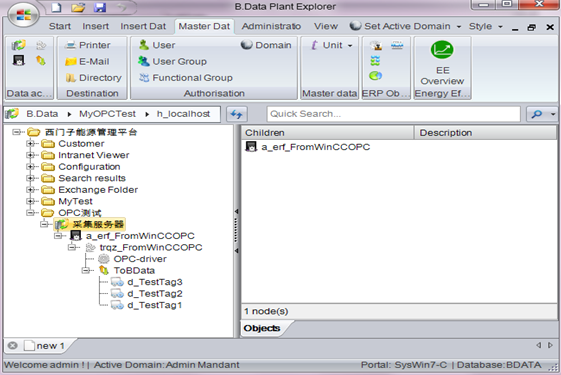

图9 配置结果

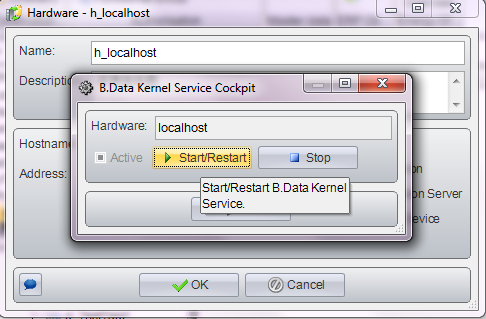

5、Kernel.exe程序的配置

完成驱动连接创建变量后,需要运行数据采集服务Kernel,如下图在采集服务器中启动相关服务,可以采用手动启动的方式:

图10 启动采集服务步骤1

图11 启动采集服务步骤2

Siemens PLM Software and Heilongjiang Feihe Dairy Co., Ltd. have signed a strategic agreement focusing on the digitalization of Feihe Dairy’s research and development, simulation and testing, as well as quality monitoring, supply chain management and production execution. With Siemens’ leading digital innovation platform and industry expertise, this cooperation can help Feihe Dairy to realize its digitalization strategy and set a benchmark for digital innovation in the Chinese dairy industry.

“Siemens PLM Software is a trusted leader in the field of digital manufacturing. In fact, our Kedong factory started cooperating with Siemens PLM Software last year in the deployment of a manufacturing execution system.” said Feng Hailong, CIO of Feihe Dairy Group. “Siemens PLM Software has a forward-looking strategy and global experience that best supports our goals and vision, as well as those of the entire Chinese dairy industry. We trust Siemens PLM Software to help us overcome the challenges in the journey to digital transformation.”

Founded in 1962 with its headquarters in Qiqihar, Heilongjiang Province, Feihe Dairy is one of the earliest milk powder producers in China. It created milk powder formula more suitable for Chinese consumers, especially for babies and infants. However, with the decades-long growth of the Chinese market and increased global competition in recent years, Feihe Dairy found itself in need of upgrading from a traditional dairy manufacturer to a modern digital enterprise; a consistent issue across the entire Chinese dairy industry.

Feihe Dairy faces many challenges in looking to transform their business model, including the areas of new product research and development, quality control, data transparency, production efficiency, and overseas acquisitions management. To address these, Feihe Dairy has achieved the whole process of control from pasture planting, large scale dairy farming, to production and processing, logistics and warehousing, channel management, and even after-sales service. It can further improve the ability of product research and development control, strengthening the construction of enterprise digital capability. After careful consideration, Feihe Dairy has selected Siemens PLM Software for its end-to-end digital innovation strategy, and its ability to integrate multiple aspects and systems to fully support the transformation to digitalization, including enterprise resource planning, product lifecycle management, manufacturing execution systems and automation. In addition, the embedded quality (LIMS) and advanced planning and scheduling (APS) functionality of Siemens’ offering were also seen as key differentiators.

Siemens’ digital innovation platform can create comprehensive and precise digital models of products and production operations as a means to manage the complexity and simulate the performance of smart products and smart production operations, helping manage data and processes within the value chain to maintain a high level of quality. It also helps to streamline and digitalize business processes within the group, which can improve efficiency in production chains. With this integrated solution, the manual process and paper files will be replaced by an automated process and digital files, which can enhance efficiency